The Drawbacks of Rubber Bale Granulators

As we mentioned, the rubber granulator machine is a one trick pony — it resizes rubber bales into more workable chunks. However, these broken-down chunks of rubber will still require additional processing before they can be delivered to the next step. Harsh chemical agents like talc are also needed to prevent the material from clumping while the rubber granulator breaks it down. The addition of these chemicals can cause environmental problems within the facility, which create a work hazard for employees and an overall degraded product.

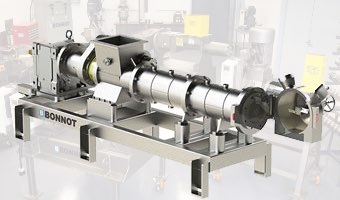

The Solution: Bonnot Rubber Bale Feeders

Between strict regulations and the specifications of our clients, the Bonnot Company has had plenty of opportunities to innovate in the field of hydrocolloid extrusion. The video below, in which Bonnot Vice President John Negrelli walks us through a complete extrusion system for a medical application, is a prime example:

Replacing a rubber granulator with a Bonnot Rubber Bale Feeder means you can remove several steps from the resizing process, reducing costs and limiting the possibility of impurities or user error interfering with your product output. Our rubber bale feeders feed full-size rubber bales directly into a downstream compounding extruder. The output rate, temperature and speed can be tightly controlled (+/- <1%) and precisely configured for the next step in the process. All of this can be accomplished without the addition of chemical agents and dusting, eliminating the environmental and safety concerns presented by rubber bale granulators.

The Bonnot Rubber Bale Feeder is available in multiple sizes and has recently been redesigned to include all the latest technological advancements in the industry. Rest assured that this redesign did not abandon the tried-and-tested feeder concept that has been used for decades, but instead improved the model overall. Our rubber bale feeders are currently in use at many of the world’s largest rubber processing companies. Check out the video below to see one of our rubber bale feeders in action!

The Bonnot Rubber Bale Feeder Processes a Lot More than Rubber

While rubber granulators can only handle rubber bales, a Bonnot Rubber Bale Feeder can be used to process a wide variety of difficult materials without pre-sizing or adding chemical agents. Our rubber bale feeding machines can tackle the following applications:

Header H2

- CPE

- EPDM

- Neoprene

- Nitrile

- SBR

- Silicone

- Vamac

- And many more!

Upgrade Your Rubber Processing Facility with Bonnot

If you’re ready to replace your old rubber granulator with a safer and more efficient rubber bale feeding machine, Bonnot is ready to help. Contact our experts today to learn more about what our Rubber Bale Feeder can do for you.