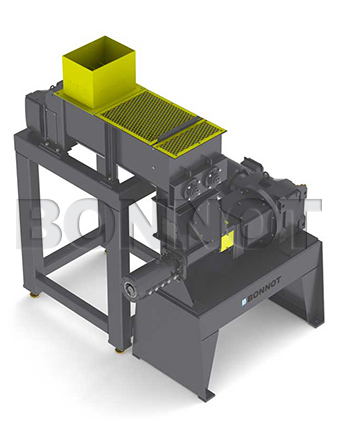

Twin Shaft Feeders

Controlled Feeding for Extrusion or Other Process Equipment

The Bonnot Company line of Twin Shaft Feeders enable a controlled material feed to optimize the downstream extruder or other process equipment. They are available in a variety of sizes depending on your need. The Twin Shaft Feeders feature variable pitch knives to change residence time and feed rate. Custom bases and orientation available to match your line layout. Feed beds can be jacketed for temperature management. Integrated controls are available to automatically vary the output rate, maintaining feed levels to optimize downstream equipment.

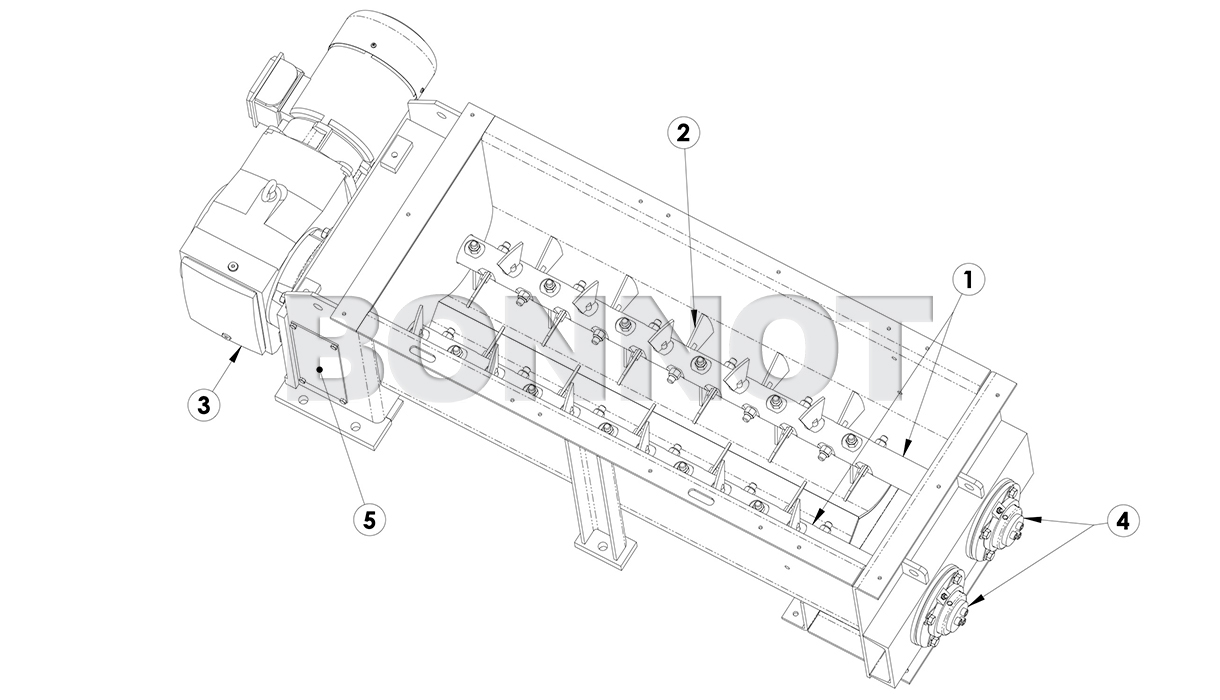

Standard Design Specifications

- Twin Shafts for large batch handling

- Variable pitch knives and gate to change residence time and output rate

- Direct Connect Gear Motor

- Custom bases and orientation available to minimize the footprint

- Sealed Gear Case for durability

Major Customers

Relevant Ancillary Equipment

Twin Packer Extruders

The industry standard in single screw extrusion.

Terrier Extruders

Robust, Durable, High Volume Processing & Easy to Maintain

Extruder Controls

The Bonnot Company Offers a Full Range of Control Options For Our Extrusion Systems

Want to Prove it Out?

The Bonnot Company is pleased to offer FREE feasibility testing in our test facility. Come and take advantage of our comprehensive catalog of test equipment; different extruder designs, screw geometries, forming dies, temperature control options, mixers and material testing equipment.