Rubber Extruders

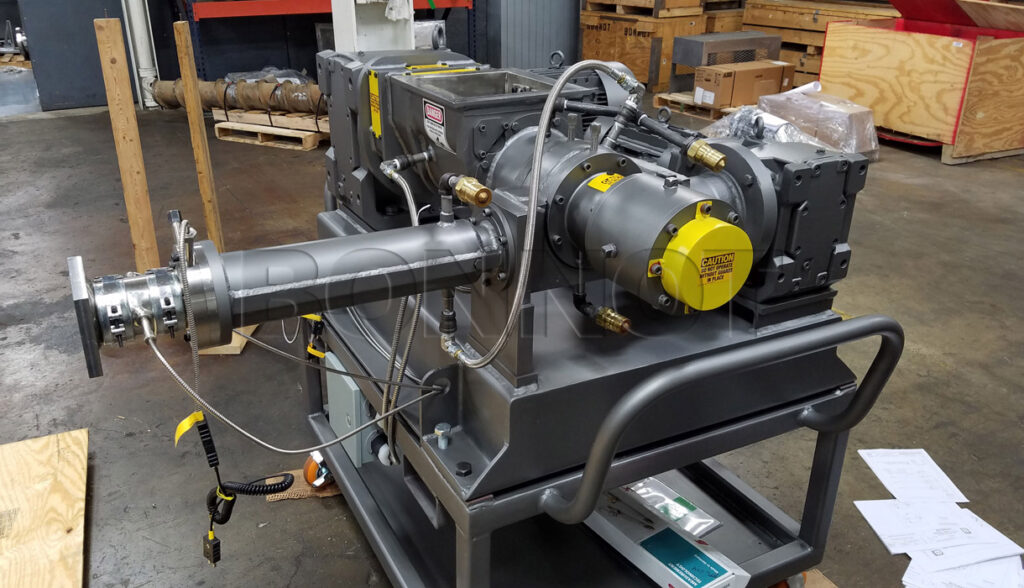

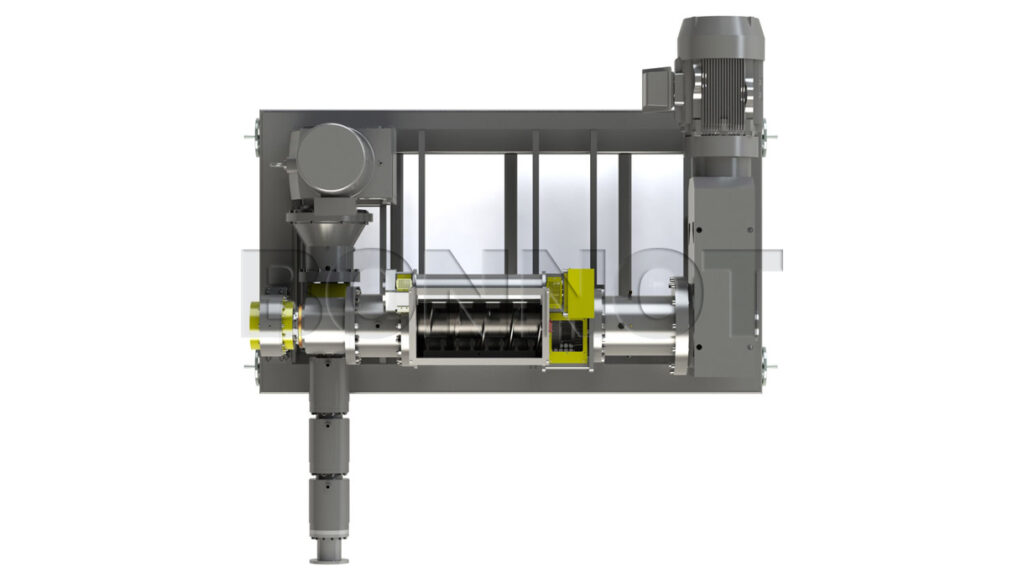

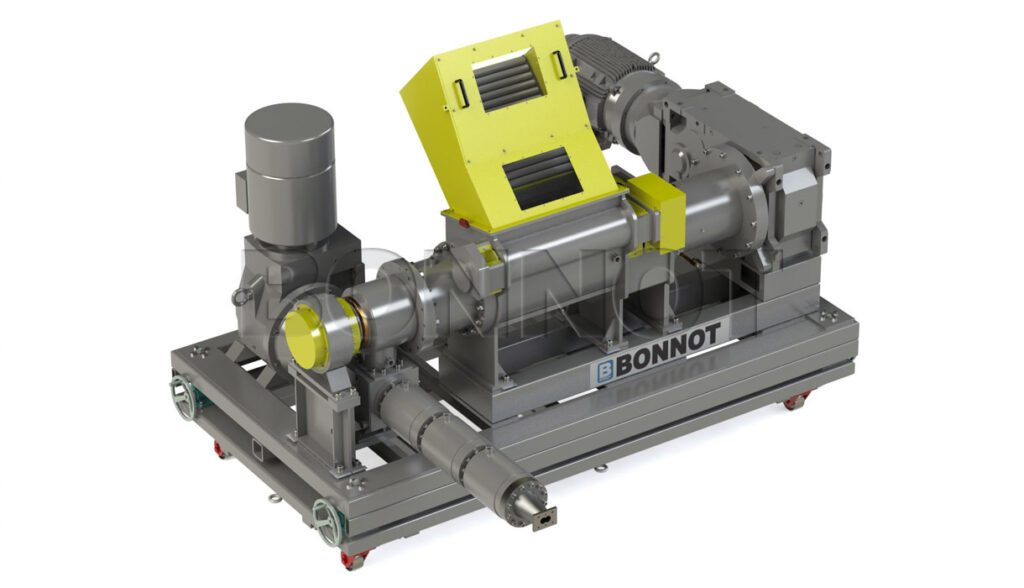

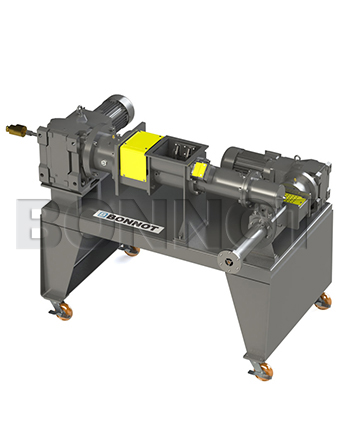

Our rubber extruders (feeders), can ingest full or partial bales of a wide range of rubbers including natural & EPDM

Rubber Bale Feeders are used for pelletizing or directly feeding a compounding extruder where the high viscosity rubber is a component in the formulation. In many plants a granulating system is currently used to grind the bale in order to introduce it into a compounding extruder. Utilizing a Bonnot Rubber Bale Feeder the entire bale is placed in the feeder, digested and accurately metered into the compounding extruder on a continual basis. The high cost and maintenance of a granulating system is eliminated. This also eliminates the need for additives such as talc.

Extruder Design Features

- Robust carbon steel or stainless steel construction

- Able to accept full bales and process in a controlled fashion

- Sizes from 2”- 8” (output screw diameter) are available

- Output metering + or - 5% without a gear pump, for 1% + or - a gear pup

- Multiple jacketed zones for temperature management

- Multiple pressure / temperature monitoring locations for control

Extruder Standard Specifications

|

Model

|

||||

|---|---|---|---|---|

| Output | 50-200 lbs/hour | 400-1200 lbs/hour | 1200-2500 lbs/hour | 2500-4000lbs/hour |

| Layout L x H x W | 51” x 64” x 54” | 80” x 80” x 54” | 100” x 156” x 82” | 110” x 156” x 82” |

| Hopper Opening | 9" x 8.5" | 18" x 13" | 30" x 18" | 36" x 18.5" |

| HP (Feed/Extusion) | 3/3 | 15/25 | 30/75 | 75/125 |

| Contact Components | Proprietary Wear Resistant Stainless Steels | Proprietary Wear Resistant Stainless Steels | Proprietary Wear Resistant Stainless Steels | Proprietary Wear Resistant Stainless Steels |

|

Model

|

RF 2 Series |

RF 4 Series |

RF 6 Series |

RF 8 Series |

|---|

Major Customers

Relevant Ancillary Equipment

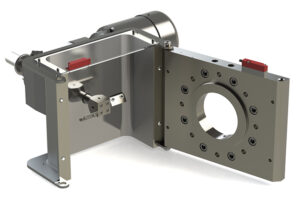

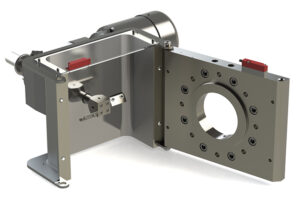

Extruder Cutter

We offer a range of cutters for our extruders.

Extrusion Dies

Bonnot Offers a Variety of Extrusion Dies in Various Sizes

Extruder Controls

The Bonnot Company Offers a Full Range of Control Options For Our Extrusion Systems

Want to Prove it Out?

The Bonnot Company is pleased to offer FREE feasibility testing in our test facility. Come and take advantage of our comprehensive catalog of test equipment; different extruder designs, screw geometries, forming dies, temperature control options, mixers and material testing equipment.