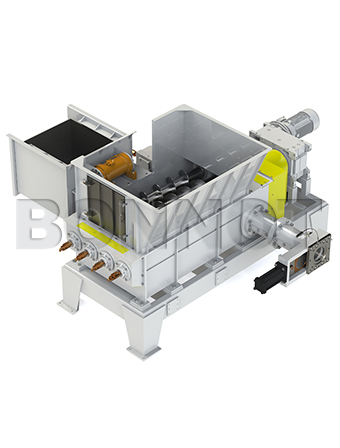

Live Bottom Extruders

Process Entire Batches of Butyl, Sealants and other Mastics

Bonnot developed the Live Bottom Feeder Extruder to efficiently process entire loads of material from the mixer, eliminating the need and cost of pre-sizing batches. Dual drives enable independent control over feeding and extrusion. Feed beds are customized to match your batch size. The Live Bottom Feeder Extruder is configured with multiple temperature zones, including screws to enhance process control. Optional hydraulic batch loading feature optional. Right or left-hand configurations to match your facility layout.

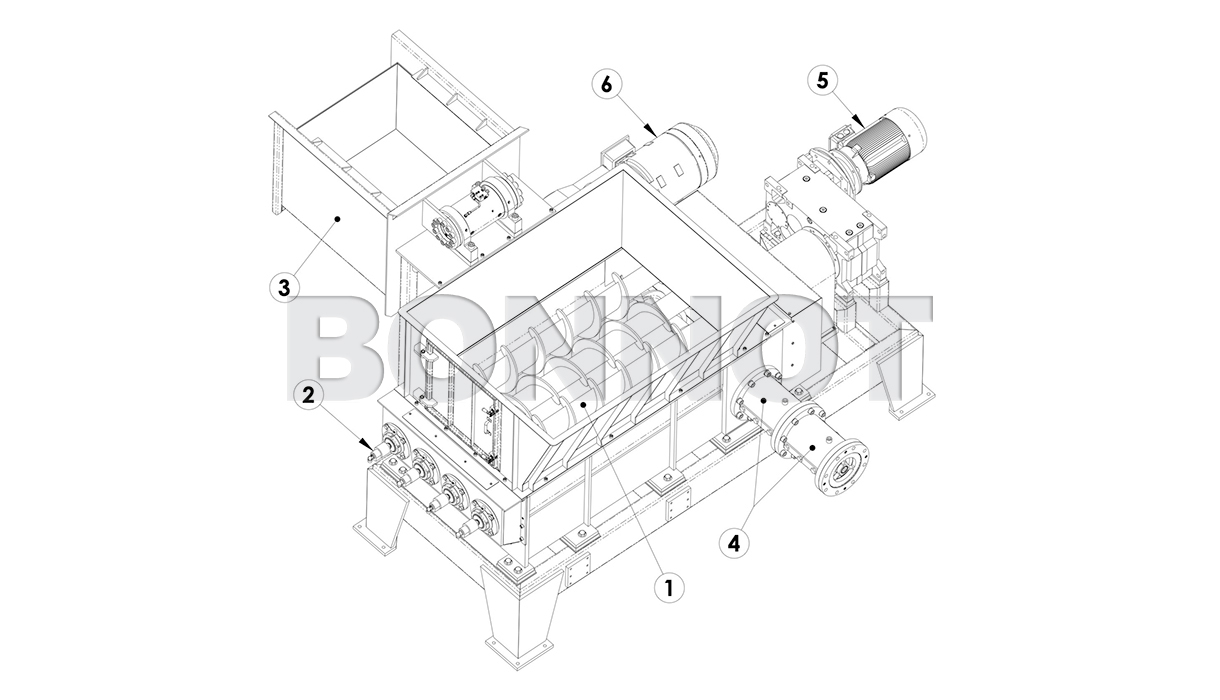

Extruder Design Features

- Large Diameter Feed Screws

- Rotary Union for Screw Temperature Control

- Hydraulic Batch Loading System

- (2) Jacketed Barrels for Temperature Control

- High Torque Feeder Motor

- High Torque Extrusion Motor

Extruder Standard Specifications

Major Customers

Relevant Ancillary Equipment

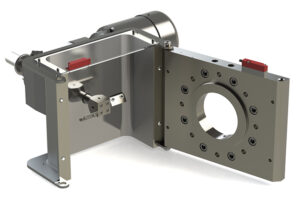

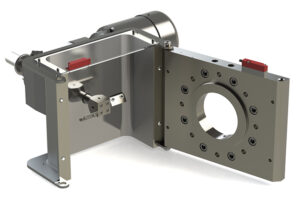

Extrusion Dies

Bonnot Offers a Variety of Extrusion Dies in Various Sizes

Extruder Cutter

We offer a range of cutters for our extruders.

Extruder Controls

The Bonnot Company Offers a Full Range of Control Options For Our Extrusion Systems

Want to Prove it Out?

The Bonnot Company is pleased to offer FREE feasibility testing in our test facility. Come and take advantage of our comprehensive catalog of test equipment; different extruder designs, screw geometries, forming dies, temperature control options, mixers and material testing equipment.