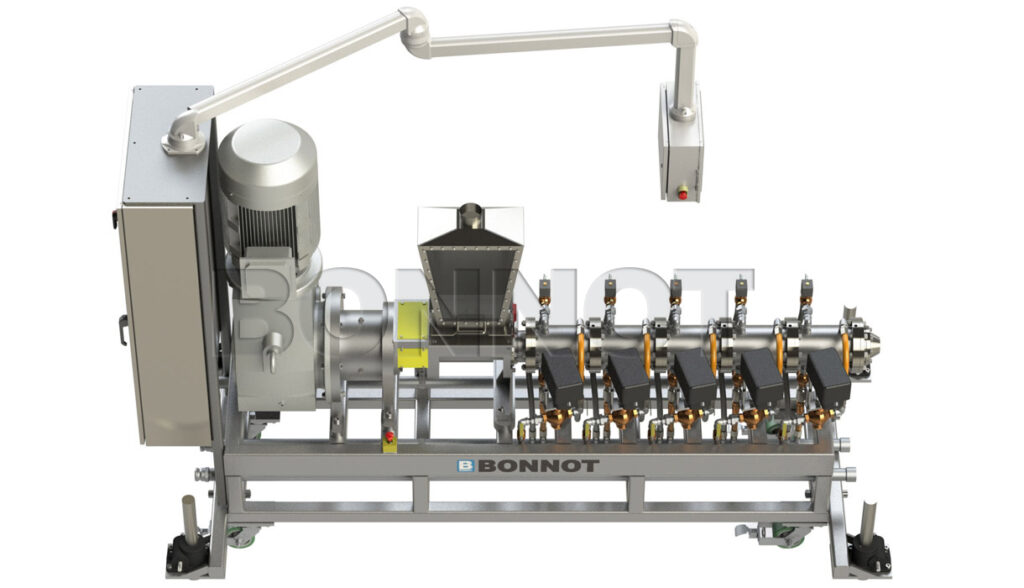

Cooking Extruders

Bonnot Cooking Extruders have been used for decades by leading food manufacturers worldwide

Bonnot Single Screw Cooking Extruders are optimized for continuous mechanical cooking of a wide variety of food products. A pre-mixed recipe is fed into a Bonnot which continuously cooks and forms a shape for cereals, animal feeds, floating fish food, CBD products and many more.

Bonnot Cooking Extruders differ from Forming extruders, having a longer L/D with multiple jacketed barrels for temperature management and deploying a hollow compression screw to induce mechanical shear through the material. The Bonnot Cooking extruders can be used in place of a traditional batch process, offering continuous cooking.

Uses: Pet food, food product development, gelatinizing starches, zoo animal feed, cereals, confectionary and many more.

Extruder Design Features

- Stainless steel construction

- Food safety standards applied

- Longer L/D (20:1+)

- Multiple zone temperature control for heating, including screw

- Compression screws induce shear and evenly heat

- Many die configurations for your application

- Heating TCU’s or electric band heaters available

Extruder Standard Specifications

|

Model

|

|||||

|---|---|---|---|---|---|

| Starting from | $60,000 | $100,000 | $150,000 | $320,000 | $480,000 |

| Output (lbs/hour) | 5-15 | 100-175 | 600-1000 | 1500-2500 | 2000-3500 |

| Approximate Layout (L x H x W) | 35" x 22" x 16" | 75" x 54" x 35" | 132" x 79" x 50" | 180" x 22" x 40" | 232" x 77" x 83" |

| Hopper Opening | 3” x 2.4” | 6” x 5” | 11.75” x 9.88” | 18” x 13.5” | 20.5” x 17” |

| Approximate Weight (lbs) | 131 | 1000 | 1600 | 7600 | 14000 |

| Motor Power (HP) | 0.5 | 10 | 25 | 75 | 125 |

|

Model

|

CO 1 Series |

CO 2.25 Series |

CO 4 Series |

CO 6 Series |

CO 8 Series |

|---|

Major Customers

Relevant Ancillary Equipment

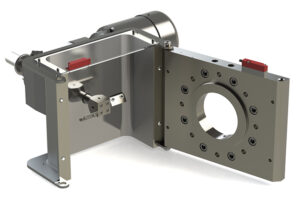

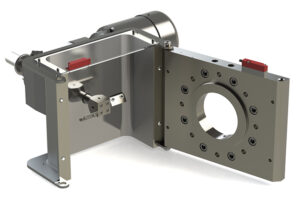

Extruder Cutter

We offer a range of cutters for our extruders.

Extrusion Dies

Bonnot Offers a Variety of Extrusion Dies in Various Sizes

Want to Prove it Out?

The Bonnot Company is pleased to offer FREE feasibility testing in our test facility. Come and take advantage of our comprehensive catalog of test equipment; different extruder designs, screw geometries, forming dies, temperature control options, mixers and material testing equipment.