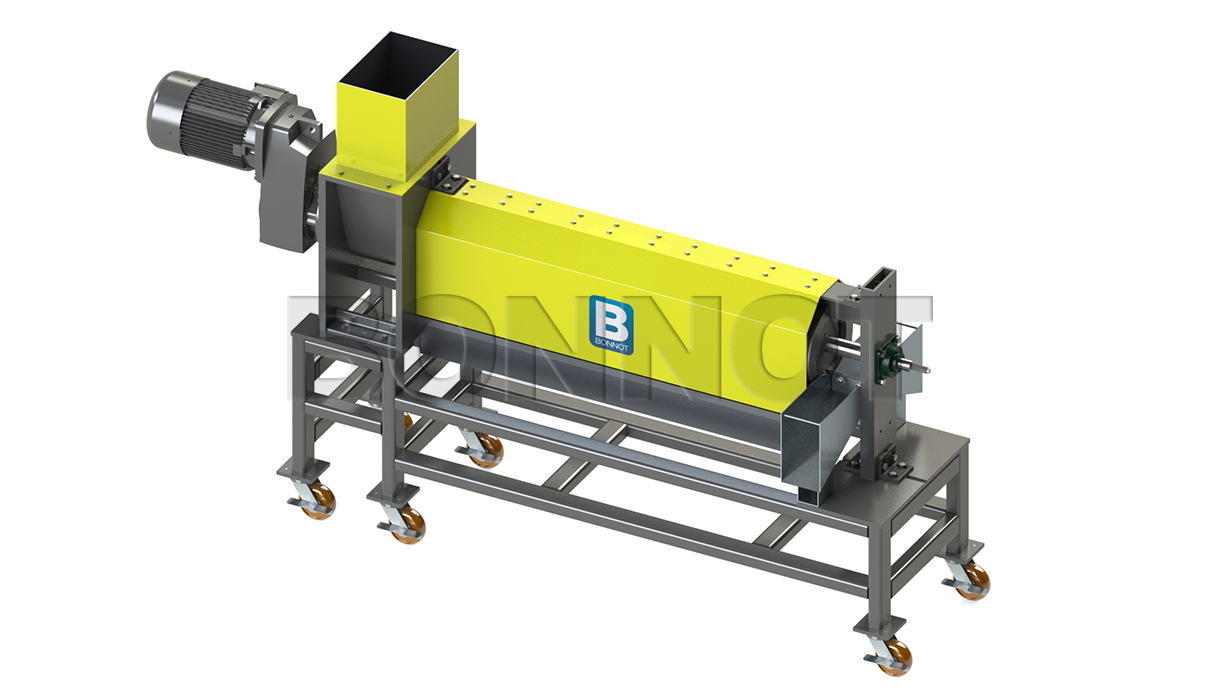

Dewatering Extruders

The Bonnot Company has a design for Dewatering Spent Grain

De-watering Wet Distillers Grain (WDG) or brewers grain is a simple process in which water is removed from the grain most often onsite, immediately after brewing to prevent rotting and increase resale value. This occurs in a continuous mechanical screw press and will reduce moisture levels to around ~ 60%, typically dry to the touch. The 60% grain can now be used for animal feeds, fertilizers or a variety of other uses, or dried further via heat methods for additional uses. This moisture level reduction greatly lengthens the shelf life of the product and significantly reduces the weight and consequently the transportation costs.

Contact us to schedule a trial.

Extruder Design Features

- Simple, robust, cost effective design

- Replaceable Stainless Steel screens

- Shrouding & Water Collection Device

Relevant Ancillary Equipment

Extruder Controls

The Bonnot Company Offers a Full Range of Control Options For Our Extrusion Systems

Want to Prove it Out?

The Bonnot Company is pleased to offer FREE feasibility testing in our test facility. Come and take advantage of our comprehensive catalog of test equipment; different extruder designs, screw geometries, forming dies, temperature control options, mixers and material testing equipment.