Chemical Catalyst Extruders

We are the number 1 catalyst extruder manufacturer in the world.

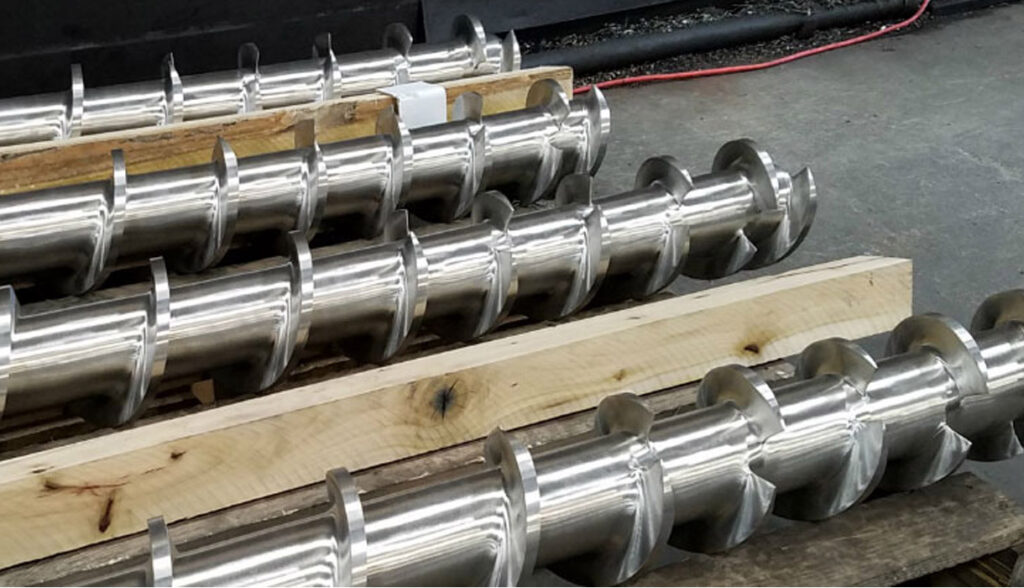

The Bonnot Catalyst Extruders are the industry standard for catalyst processing. Every part of the design is optimally configured for processing abrasive catalyst materials. Materials of construction are chosen to last, and engineering enhancements make wearing parts quick and easy to replace. Our Twin Packer design aids material ingestion by reducing bridging in the feed hopper. When properly maintained, our catalyst extruders will run for decades.

Chemical catalysts are typically used for creating chemical reactions in oil refining and other processes.

Extruder Design Features

- Extrude high surface area shapes such as cylinders, hollow tubes, trilobe, quadlobe & more

- Designed for continuous production with proven wear resistant replacable contact components

- Customized and configured for the specific application

- Auger rebuild program and barrel liner replacement service

- Temperature control features

- 50+ years of proven operation with worldwide install base

Extruder Standard Specifications

|

Model

|

|||||

|---|---|---|---|---|---|

| Output | 5-15 lbs/hour | 100-175 lbs/hour | 600-1000 lbs/hour | 1500 - 2500+ lbs/hour | 2000 - 3500+ lbs/hour |

| Layout L x H x W | 21" x 22" x 16" | 43" x 54" x 35" | 76" x 79" x 50" | 96" x 82" x 40" | 120" x 77" x 83" |

| Hopper Opening | 3” x 2.4” | 6” x 5” | 11.75” x 9.88” | 18” x 13.5” | 20.5” x 17” |

| Motor Power (HP) | 0.5 | 10 | 25 | 75 | 125 |

| Contact Components | Propriatary Wear Resistant Stainless Steels | Propriatary Wear Resistant Stainless Steels | Propriatary Wear Resistant Stainless Steels | Propriatary Wear Resistant Stainless Steels | Propriatary Wear Resistant Stainless Steels |

|

Model

|

CT 1 Series |

CT 2.25 Series |

CT 4 Series |

CT 6 Series |

CT 8 Series |

|---|

Relevant Ancillary Equipment

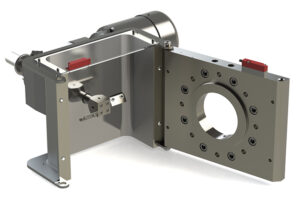

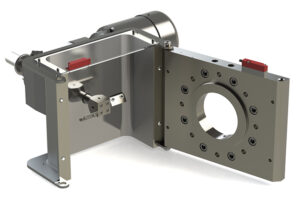

Extrusion Dies

Bonnot Offers a Variety of Extrusion Dies in Various Sizes

Extruder Cutter

We offer a range of cutters for our extruders.

Extruder Controls

The Bonnot Company Offers a Full Range of Control Options For Our Extrusion Systems

Want to Prove it Out?

The Bonnot Company is pleased to offer FREE feasibility testing in our test facility. Come and take advantage of our comprehensive catalog of test equipment; different extruder designs, screw geometries, forming dies, temperature control options, mixers and material testing equipment.