Fire Log Extruders

Robust, Durable, High Volume Processing & Easy to Maintain

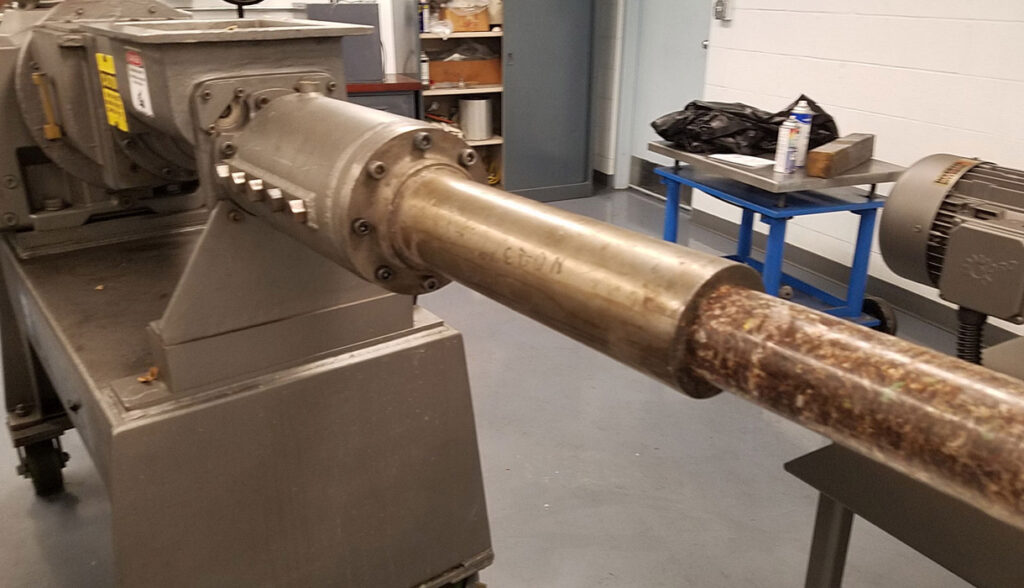

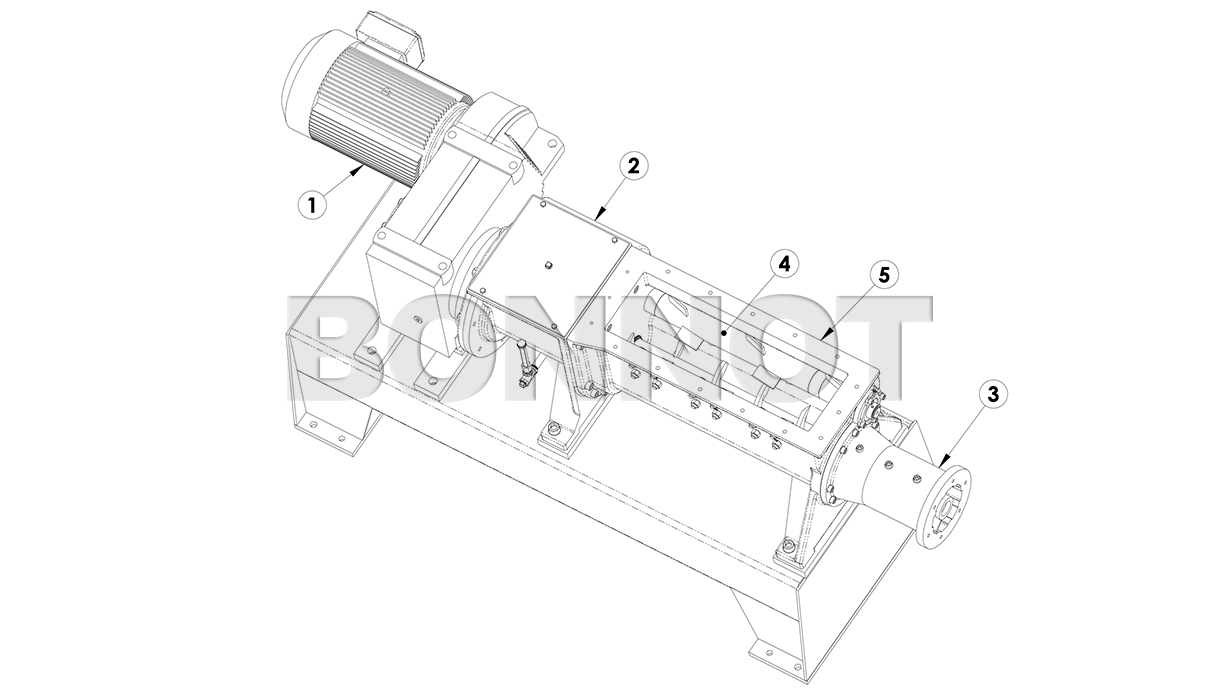

The Bonnot Company builds high volume, rugged, robust designs for producing Fire Logs and Fire Starters. These machines are ‘brickyard’ style, built to provide years of service with minimal maintenance. Our equipment accepts a wax and wood feedstock formula directly from the mixer and creates a uniform profile and density of your desired size/shape.

Extruder Design Features

- High Torque Drive

- Robust Gear Box

- Jacketed, Grooved Barrel (optional)

- Counter Rotating Packer

- Jacketed Hopper (optional)

Relevant Ancillary Equipment

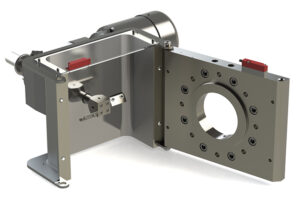

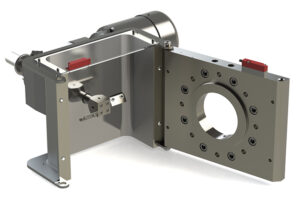

Extruder Cutter

We offer a range of cutters for our extruders.

Extrusion Dies

Bonnot Offers a Variety of Extrusion Dies in Various Sizes

Extruder Controls

The Bonnot Company Offers a Full Range of Control Options For Our Extrusion Systems

Want to Prove it Out?

The Bonnot Company is pleased to offer FREE feasibility testing in our test facility. Come and take advantage of our comprehensive catalog of test equipment; different extruder designs, screw geometries, forming dies, temperature control options, mixers and material testing equipment.