Soft Rubber & Sealants Extruders

We have a long history of processing soft rubbers for sealants and adhesives

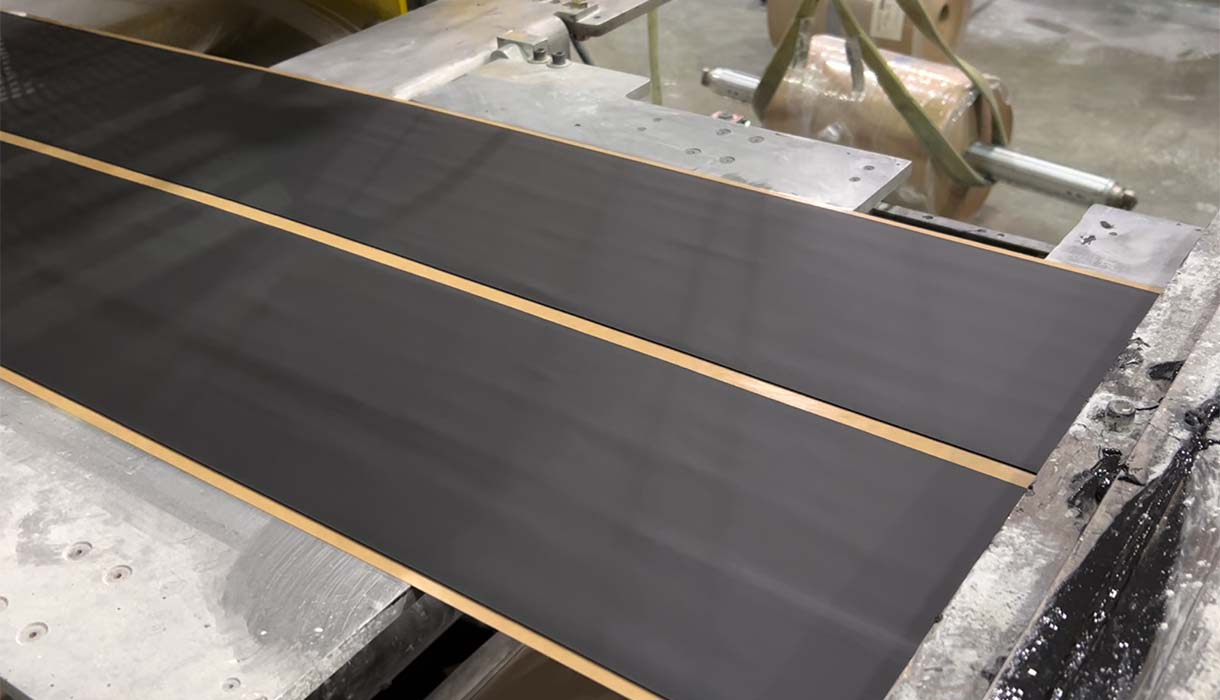

The Bonnot Company builds various designs for processing a variety of butyl and mastic rubbers. Depending on the size and configuration you select, our equipment can accept soft rubber feedstock ranging from small pieces/ropes to full batches straight from your mixer. Often, the goal is to create a more manageable profile for downstream processing or creating various size strips feeding directly onto a roller/slitting equipment to create the final product.

Extruder Design Features

- High volume cost effective, robust designs

- Temperature control

- Customizable layouts and centerlines

- Customizable feed area sizing

- Batch loading options available

- Gear Motor HP and speeds customized to each installation

- Bench-top models available for smaller outputs

Extruder Standard Specifications

|

Model

|

|||||

|---|---|---|---|---|---|

| Output | 600-1000 lbs/hour | 600-800 lbs/hour | 400-800 lbs/hour | 1,000 - 2,500 lbs/hour | 2500 - 4,500 lbs/hour |

| Approximate Layout (L x H x W inches) | 51” x 64” x 54” | 86” x 60” x 29” | 76" x 79" x 50" | 124” x 105” x 108” | 190” x 128” x 59” |

| Hopper Opening | 11.75” x 9.88” | 18” x 13.5” | 20.5” x 17” | 48” x 36-1/4” | 86-1/8” x 48” |

| HP | 15/25 | 40 | 25 | 25/75 | 40/100 |

|

Model

|

RS 4 Series DD |

RS 4 Series T |

RS 4 Series TP |

RS 6 Series LB |

RS 8 Series LB |

|---|

Major Customers

Relevant Ancillary Equipment

Extrusion Dies

Bonnot Offers a Variety of Extrusion Dies in Various Sizes

Extruder Controls

The Bonnot Company Offers a Full Range of Control Options For Our Extrusion Systems

Want to Prove it Out?

The Bonnot Company is pleased to offer FREE feasibility testing in our test facility. Come and take advantage of our comprehensive catalog of test equipment; different extruder designs, screw geometries, forming dies, temperature control options, mixers and material testing equipment.