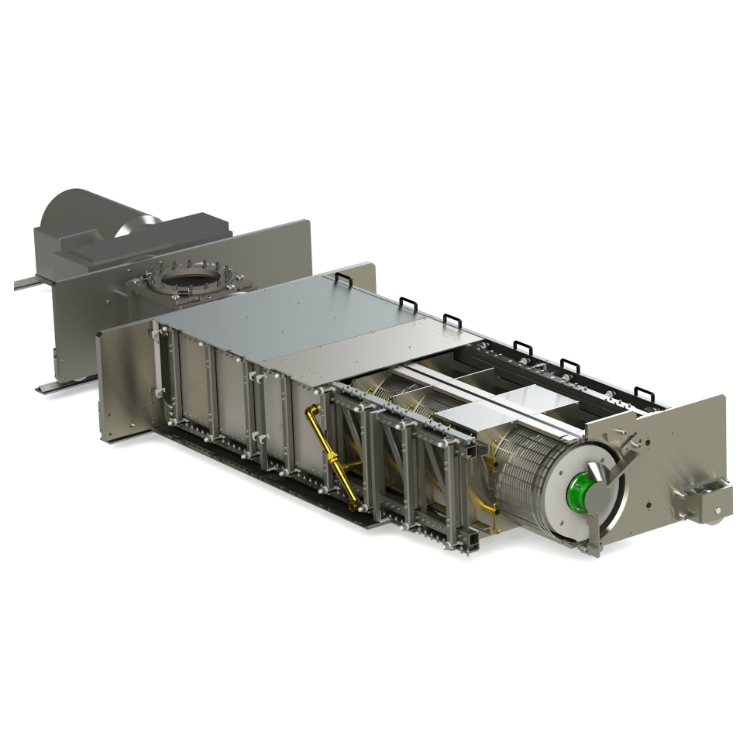

Dewatering Extruder

Product Information

The Bonnot Company has developed a new line of dewatering extruder equipment for the ethanol, distilling, paper pulp, and brewing industries. Our extruder equipment is capable of handling wet distillers grain (WDG), at high levels of moisture and reduce it to the specification required. Capacity of our equipment can reach as high as 40 tons per hour. Our Dewatering Extruders are compact and require significantly less power when compared with traditional dewatering equipment. From the small microbrewery to the largest ethanol plant we can deliver the right equipment for a fraction of the cost.

Bonnot has been at the forefront of dewatering spent grains with our patented single screw, continuous extrusion process. We have patented technology that allows customers large and small to dewatering their grain to different levels.

- Wet Distellers Grain: 65% – 70% moisture

- Modified Wet Distillers Grain: 50% – 55% moisture

- Dried Distillers Grain: 10% moisture

*FOB Plant Prices (USDA data as of August 10, 2018)

Depending on how many batches you make per week or how many pounds you need to put in a truck will determine the size of the machine and finished moisture contents possible. Many brewers just send the non-dewatered grain to farms just to avoid having to pay tipping fees for disposal. With our equipment you can start make some money and get $25-$55 per ton (depending on region). Our you could make even more money by dewatering to a Modified Wet state and get $45-$75 per ton (depending on the region).

We can customize our equipment to your specific facility needs and show a quick ROI. We work with many companies that are forming co-ops consisting of small micro-breweries to bring their spent grains to one depot to process larger quantities. This helps spread the capital equipment costs over many people and makes it more feasible for all brewers large and small. With so many small, amazing brewers popping up this industry is fast growing.

Finally, dewatering your spent grain avoids putting it in the landfill. This value add to your company will show your loyal customers you do care about the environment by reducing waste.

Employing Bonnot Company processing equipment — whether in compounding or in food-related applications — for the processing of spent grains ensures rapid mass production so the resulting product can be easily distributed or used again in another application.

Whatever your spent grain application may be, we can provide an extrusion solution that will keep you productive and ensure that no material is wasted.

Dewatering Extruder Processing Spent Grains

Contact our Bonnot Experts and we will be in touch within 1-2 business days to discuss your needs.